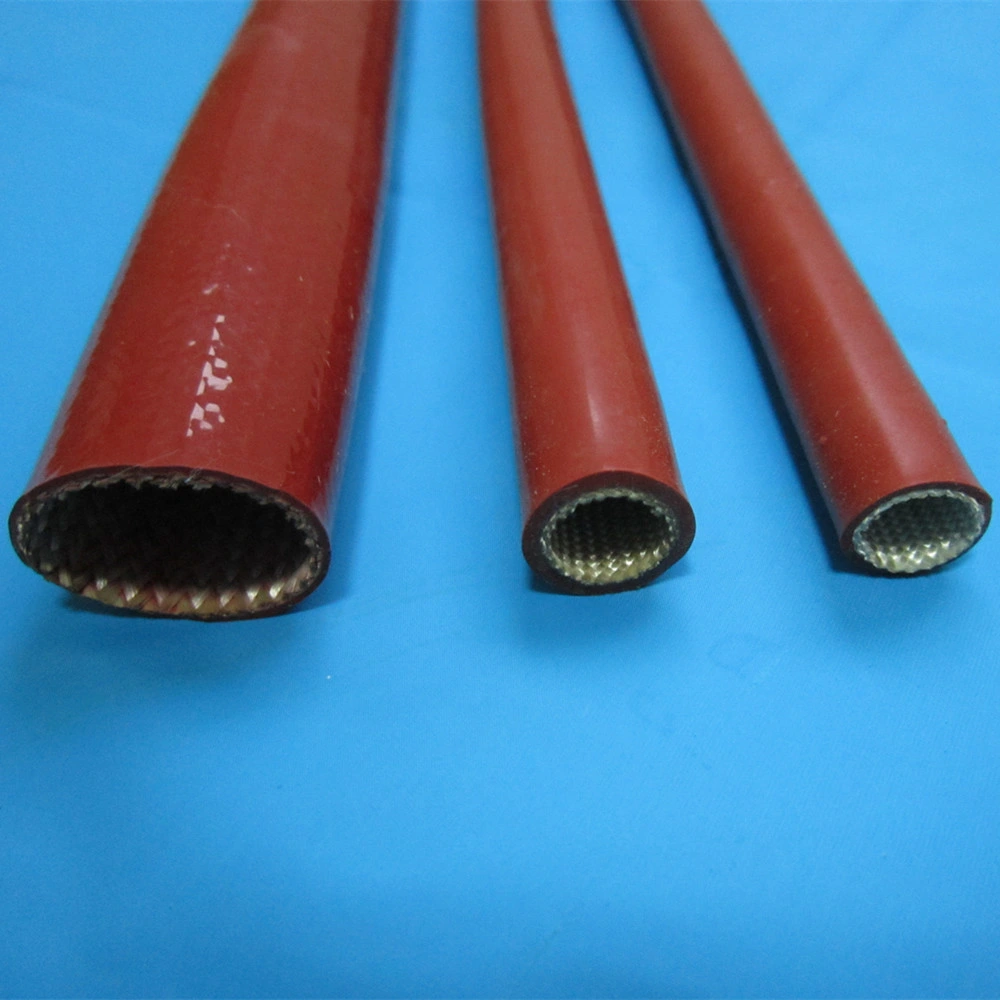

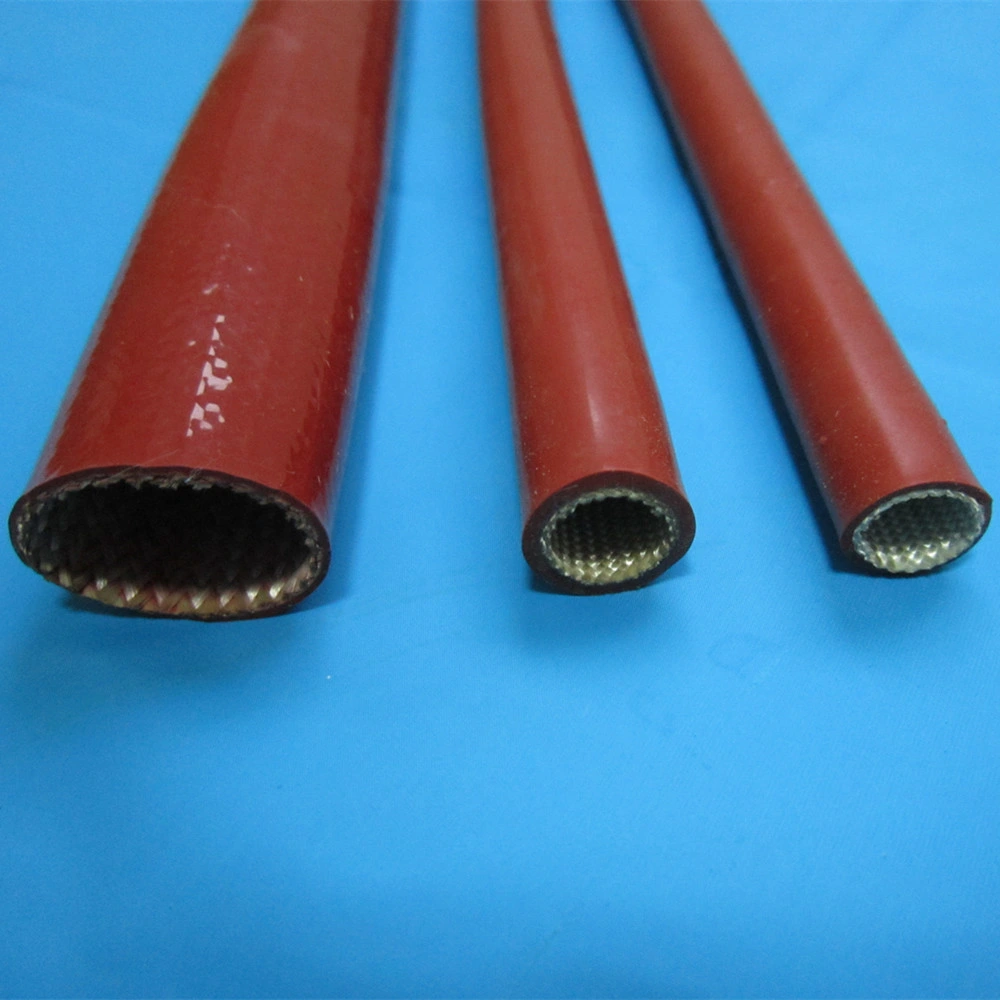

BST-FGS-SR Silicone Resin Fiberglass Sleeve is non-alkali fiberglass braided sleeve coated with silicone resin. Silicone Resin Fiberglass Sleeve is treated at a suitably high temperature to prossess excellent flexibility, toughness, self-extinguishment and dielectric strength, and to obtain a temperature classification of 200°C.

It has especially good radiation resistance in addition to resistance to ozone, moisture, corona, weathering, fungus and chemical attack.

It is used in aerospace installations. It is used in the class H insulation system of electric motors,appliances,heating equipments,apparatus machinery,etc.

It has especially good radiation resistance in addition to resistance to ozone, moisture, corona, weathering, fungus and chemical attack.

It is used in aerospace installations. It is used in the class H insulation system of electric motors,appliances,heating equipments,apparatus machinery,etc.

| DATASHEET | |||||||||

| Part Number | Bore Diameter (mm) | Wall Thickness (mm) | Meter for spool | ||||||

| Normal | Tolerance | A | B, C, D | Meter | |||||

| BST-FGS-SR-0.5 | 0.5 | 0.25 | 0.18 | 0.38 | 200 | ||||

| BST-FGS-SR-0.8 | 0.8 | 0.25 | 0.18 | 0.38 | 200 | ||||

| BST-FGS-SR-1 | 1 | 0.25 | 0.18 | 0.38 | 200 | ||||

| BST-FGS-SR-1.5 | 1.5 | 0.25 | 0.18 | 0.38 | 200 | ||||

| BST-FGS-SR-2 | 2 | 0.25 | 0.18 | 0.38 | 200 | ||||

| BST-FGS-SR-2.5 | 2.5 | 0.25 | 0.18 | 0.38 | 200 | ||||

| BST-FGS-SR-3 | 3 | 0.5 | 0.23 | 0.46 | 200 | ||||

| BST-FGS-SR-3.5 | 3.5 | 0.5 | 0.23 | 0.46 | 200 | ||||

| BST-FGS-SR-4 | 4 | 0.5 | 0.23 | 0.46 | 200 | ||||

| BST-FGS-SR-4.5 | 4.5 | 0.5 | 0.28 | 0.5 | 100 | ||||

| BST-FGS-SR-5 | 5 | 0.5 | 0.28 | 0.5 | 100 | ||||

| BST-FGS-SR-6 | 6 | 0.5 | 0.28 | 0.5 | 100 | ||||

| BST-FGS-SR-7 | 7 | 0.6 | 0.28 | 0.5 | 100 | ||||

| BST-FGS-SR-8 | 8 | 0.6 | 0.28 | 0.5 | 100 | ||||

| BST-FGS-SR-9 | 9 | 0.6 | 0.28 | 0.5 | 100 | ||||

| BST-FGS-SR-10 | 10 | 0.8 | 0.4 | 0.6 | 100 | ||||

| BST-FGS-SR-12 | 12 | 0.8 | 0.4 | 0.6 | 100 | ||||

| BST-FGS-SR-14 | 14 | 0.8 | 0.48 | 0.68 | 50 | ||||

| BST-FGS-SR-16 | 16 | 0.8 | 0.48 | 0.68 | 50 | ||||

| BST-FGS-SR-18 | 18 | 0.8 | 0.48 | 0.68 | 50 | ||||

| BST-FGS-SR-20 | 20 | 1 | 0.5 | 0.7 | 50 | ||||

| BST-FGS-SR-22 | 22 | 1 | 0.5 | 0.7 | 25 | ||||

| BST-FGS-SR-25 | 25 | 1 | 0.5 | 0.7 | 25 | ||||

| BST-FGS-SR-30 | 30 | 1 | 0.5 | 0.7 | 25 | ||||